Remanufacturing

We Are Determined To Bring Renewed Life To Your Experienced Products.

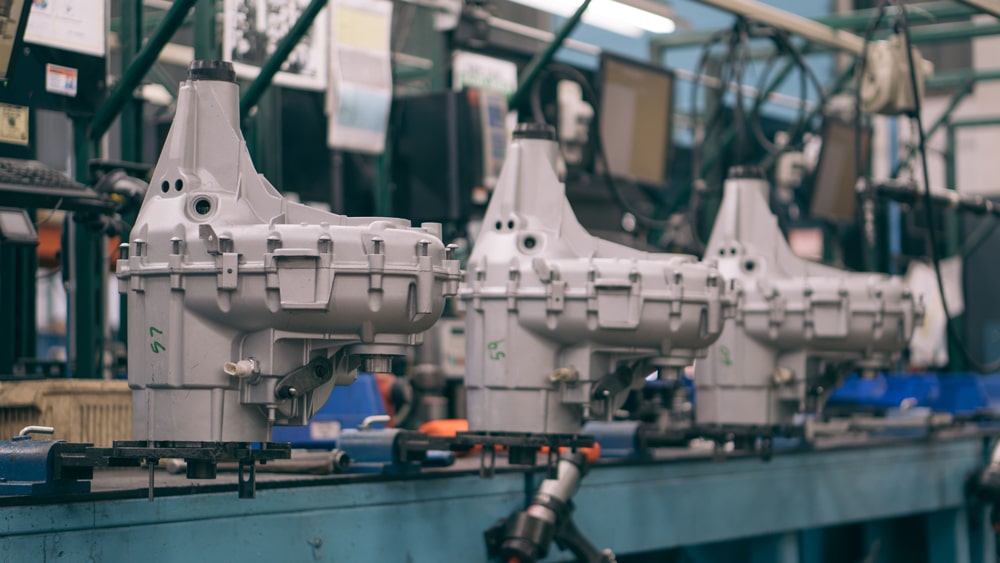

Dependable Remanufactured Transmissions For Every Vehicle

At Dynamic Manufacturing, we are a major supplier of reliable and effective remanufactured vehicle pieces. Our teams produce items like torque converters, automatic transmissions, transfer case assemblies, and engines with careful and sustainable remanufacturing processes. You can extract maximum value from your experienced parts with Dynamic Manufacturing.

The process of remanufacturing produces components that offer the same quality and durability as the originals while saving the costs and resources associated with the production of new materials.

What Is Remanufacturing?

According to the Remanufacturing Industries Council remanufacturing is a comprehensive and rigorous process by which a previously used part is returned to a like-new, same-as-when-new, or better-than-when-new condition from both a quality and performance perspective, through a controlled, reproducible, and sustainable process. Remanufacturing is not the same as rebuilding, repairing, or refurbishing.

Must Read: Remanufacturing: Paving The Way For A Greener Future In The Automotive Industry

The Benefits of Dynamic Remanufacturing

Quality

Learn More

Sustainability

Learn More

LEARN MORE

Efficiency

Learn More

Our Remanufacturing Standards

Remanufacturing doesn’t have to mean sacrificing quality or integrity. When done correctly, rebuilt transmissions offer the same longevity and reliability as original products. At Dynamic Manufacturing, we implement remanufacturing standards and check all internal components for guaranteed quality throughout the entire process:

- Hard part inspections

- Soft part replacements

- Original Equipment Service (EOS) specifications

- Documenting and replacing non-compliant parts

WHY CHOOSE DYNAMIC MANUFACTURING?

Our team at Dynamic Manufacturing has a long-standing history of expertise and dedication. Our services now expand to seven facilities around the country. Each facility works on sustainable and renewable energy sources and offers full-service operations that produce products with consistent and thorough quality assurance standards.

When you need remanufactured transmissions with guaranteed quality and durability, our team at Dynamic Manufacturing can provide them for you.

Contact our experts at Dynamic Manufacturing with any questions regarding the process and quality of remanufactured transmission by calling us at 708-343-8753.